There is indeed dynamic management from your buying teams to alleviate the impact which has been very successful. This dynamic management has also reduced the impact of the second wave associated with our inflationary wave: shortage.

My colleague Ken illustrated this point clearly in his short video “Don’t get run over by inflation ” posted on LinkedIn. During the last few months, we have all felt the impact of inflation; vendors have been extremely effective at communicating rises they were not able to offset.

At successful organisations, we have seen the dynamic approach, which basically consists of multiplying the sources for both key and less key products, softens the blow of crazy supplier letters asking for $100 a ton or 10% increase on steel every three weeks.

Inflation is important and “dramatic”, true, but may be less impactful than previous cases of localised inflation, because it can definitely also help your business to pass on that increase to your clients. Margins will be indeed affected but it has been proved that it has also been relatively possible to pass it on to the clients.

Why are we calling hysteresis the killer hill that could take your business down?

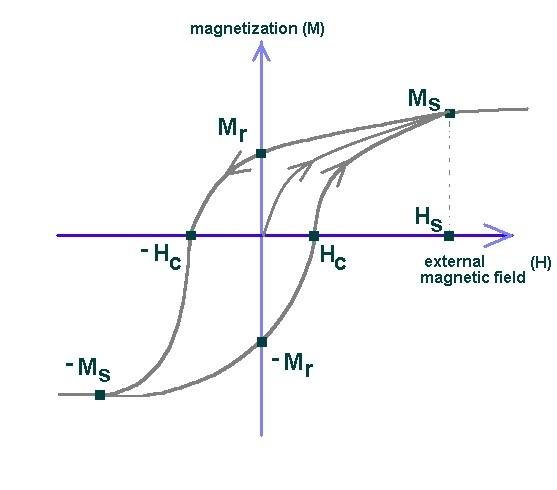

Hysteresis is the phenomenon in which the value of a physical property lags behind changes in the effect causing it. In the procurement world it means you as a vendor are quick at reporting price increases – the physical property being the lack of raw materials – but less forthcoming when reporting deflation.

It might look premature to talk about deflation now when governments around the world are forecasting double-digit consumer inflation for the coming year. In the supply chain, we have already seen green shoots of deflation and we believe that in most of your businesses you are already seeing a potential slowdown of the acceleration, and even in some cases plateauing of sales!

After two years of incredible work, your procurement team might welcome the expected ‘relief’ and successful businesses will once again take preventive measures to manage vendors.

Here are some successful approaches encountered in the past:

- Procurement using similar letters to vendors informing them that due to the increase in raw materials and increase in availability, they can expect price revisions down. Surprisingly effective if solidly prepared.

- RFP with reduced volume. This is a good one; countless times we have been told: “Oh no, I can’t do a market consultation my volume is going down.” That does not matter if your competitors’ volume is also going down.

- Cost breakdown analysis followed up by strong negotiation. Often a follow-up of to 1, above. We are always surprised with the lack of curiosity about the level-2 vendors behind your vendor. At the end of the day, your direct vendor has, at best, 10% room for manoeuvre on prices because the rest is either raw material purchased or transformation, but the raw material suppliers have the same 10%.

- Do I need to explain here that this is not all about price, but about value, and services? Faster delivery, reengineering therefore gaining in strong category management, QBR review etc… produce huge positive impact.

Hysteresis or, less technically, lethargy is not an option even if your procurement team deserves a huge break after the incredible work they have delivered in terrible conditions.